Your cart is currently empty!

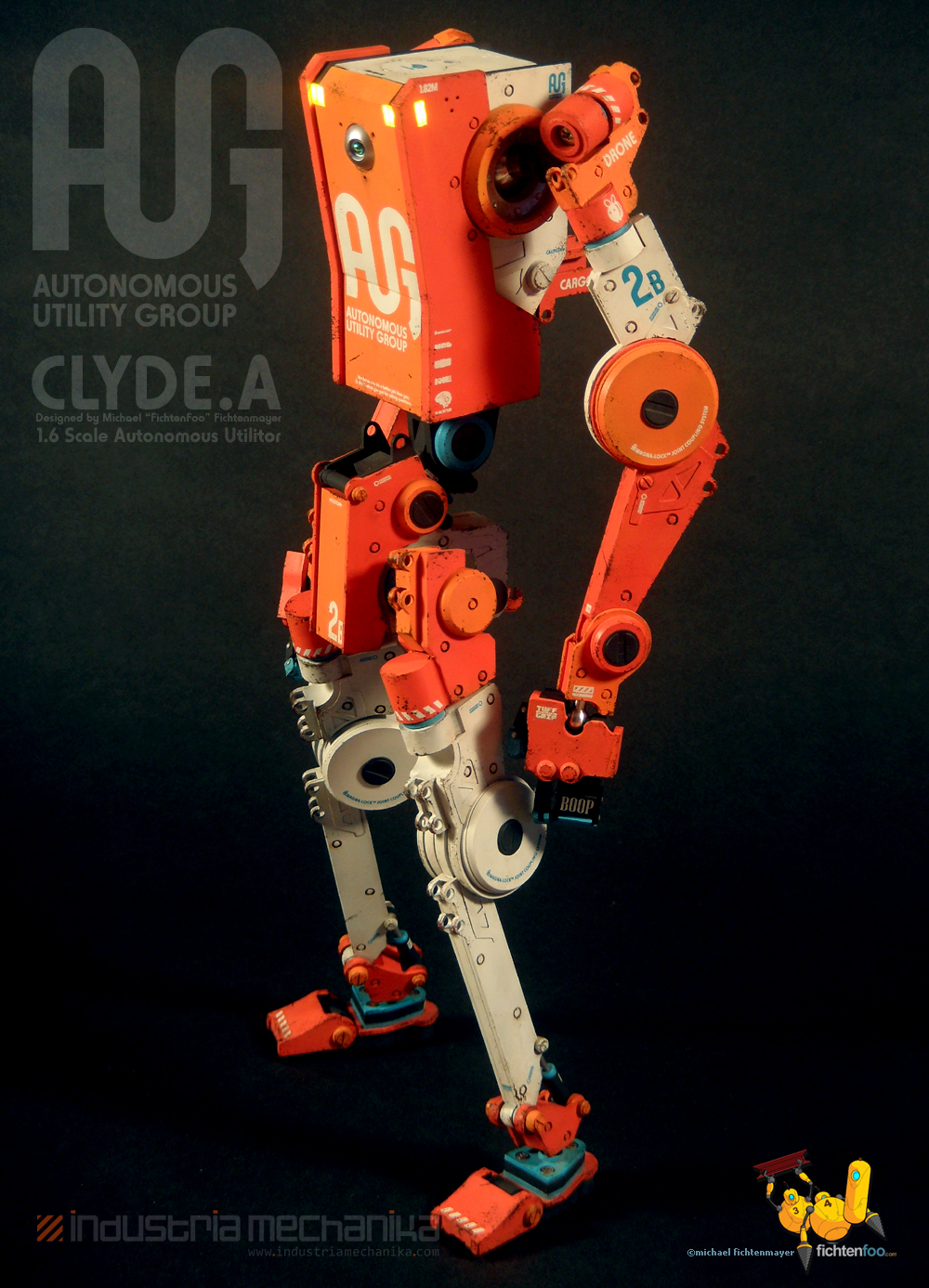

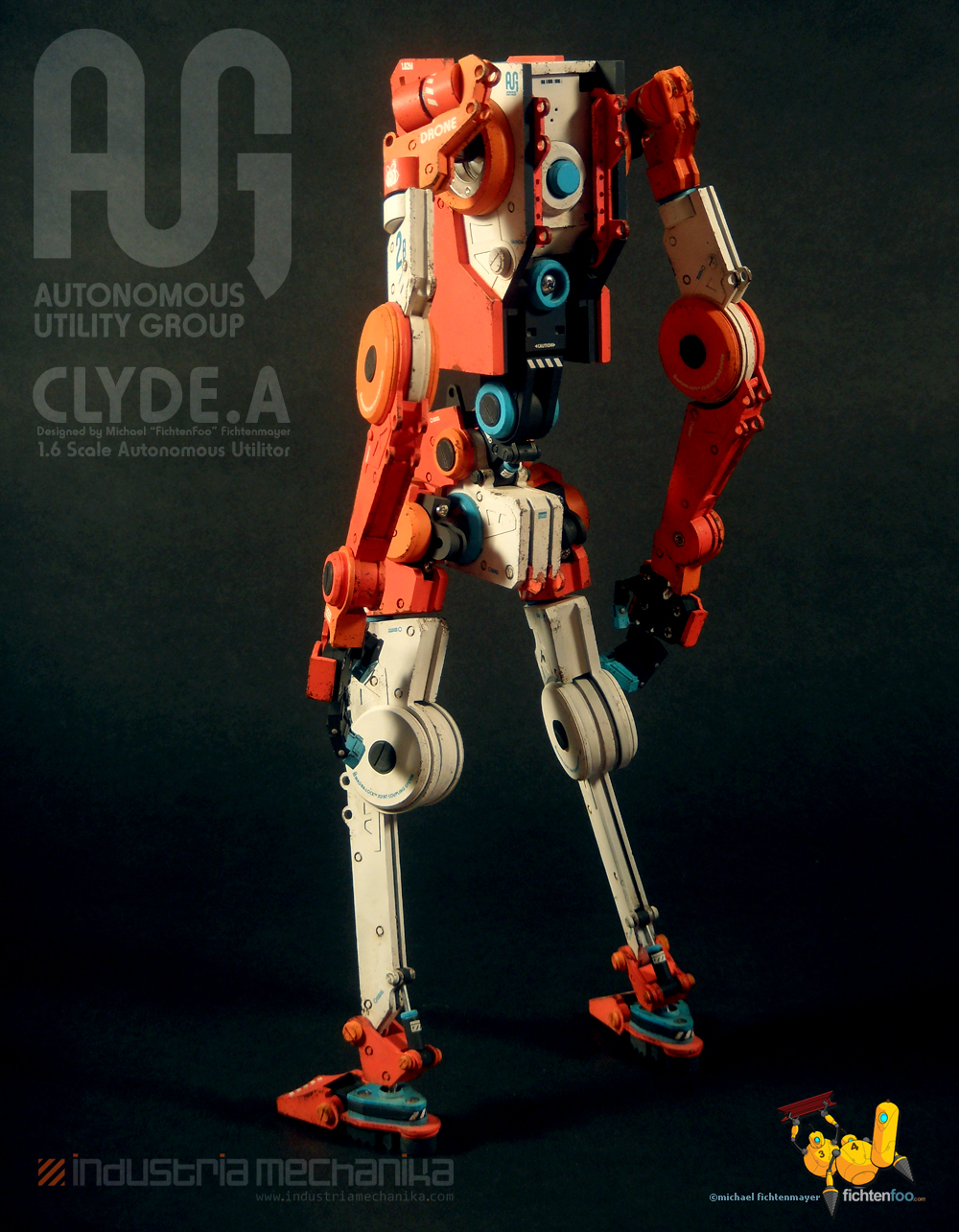

Completed » Clyde.A Autonomous Utilitor

Order the Clyde.A Full-Action 1:6 Robot Kit Exclusively at Industria Mechanika!

When I first started my company, Industria Mechanika, I fully expected to be making 6+ new kit designs a year on my own, by hand. That mindset didn’t last long thanks to collaborations and 3D printing and before I knew it, I’d only made 1-2 of my own sculpts a year as kits and then it was none at all. Mostly because Steampunk’s popularity fizzled out and I had a few more designs in me that I ended up having to mothball since they likely would not had sold well enough to justify the time expenditure. That kind of bummed me out. Sure, I was (am) producing amazing and unique model kits with amazing artists, but I kind of pushed all of my own stuff into the background.

But while I was not producing my own designs as kits, I was still building and designing up a storm, mostly in 1/6 scale. My love of robots kept bringing me back, trying to do some cool robotics in 1/6 and have the designs be fully articulated. I designed and prototyped quite a few things culminating in a large 1/6 Exo-Suit that ended up not working as planned. But that’s the thing about failure… it teaches you as much, if not more than your successes and so I decided that I needed to come up with a new line of FichtenFoo designs and what better than to go back to my first love: robots and mecha!

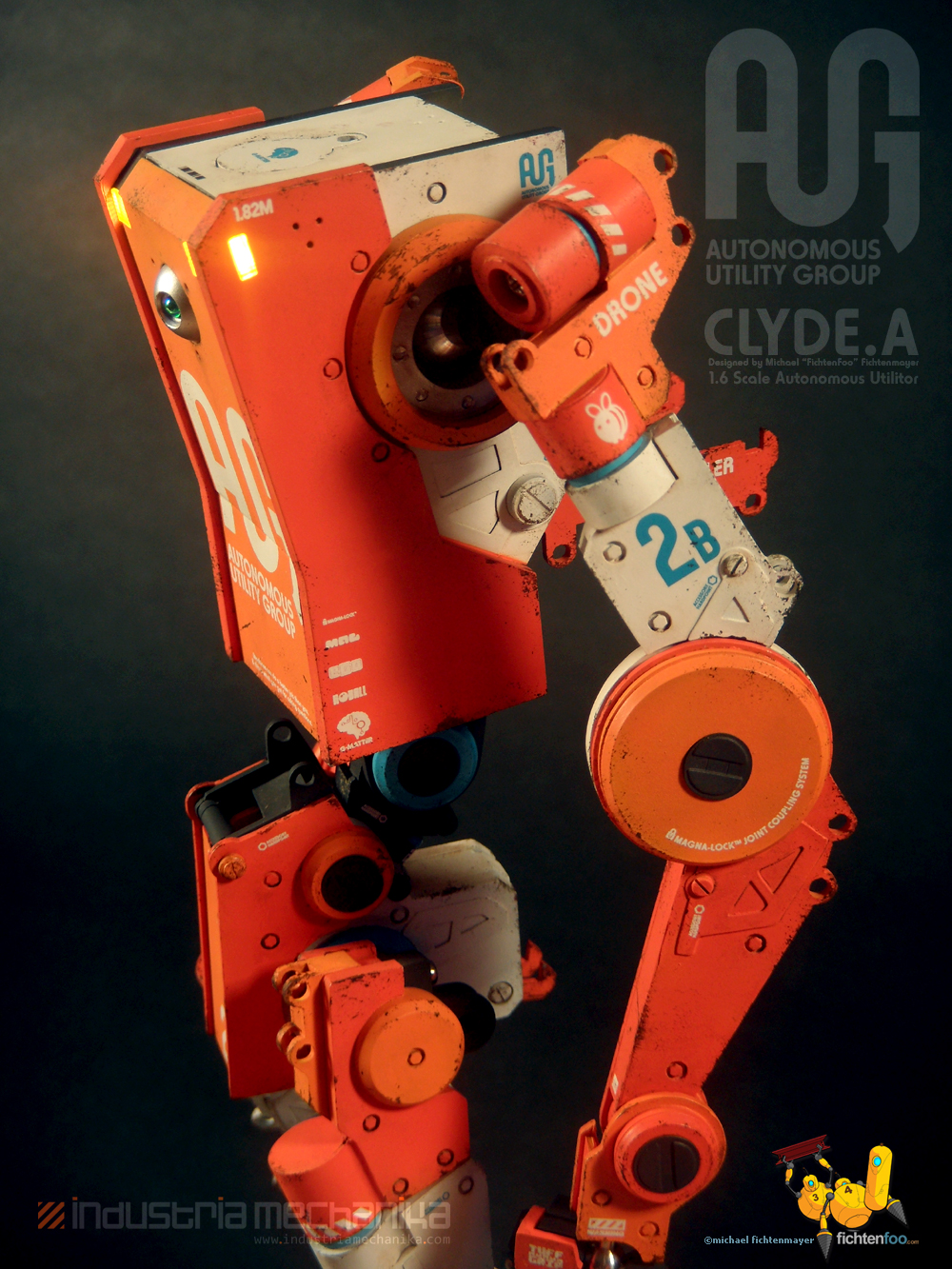

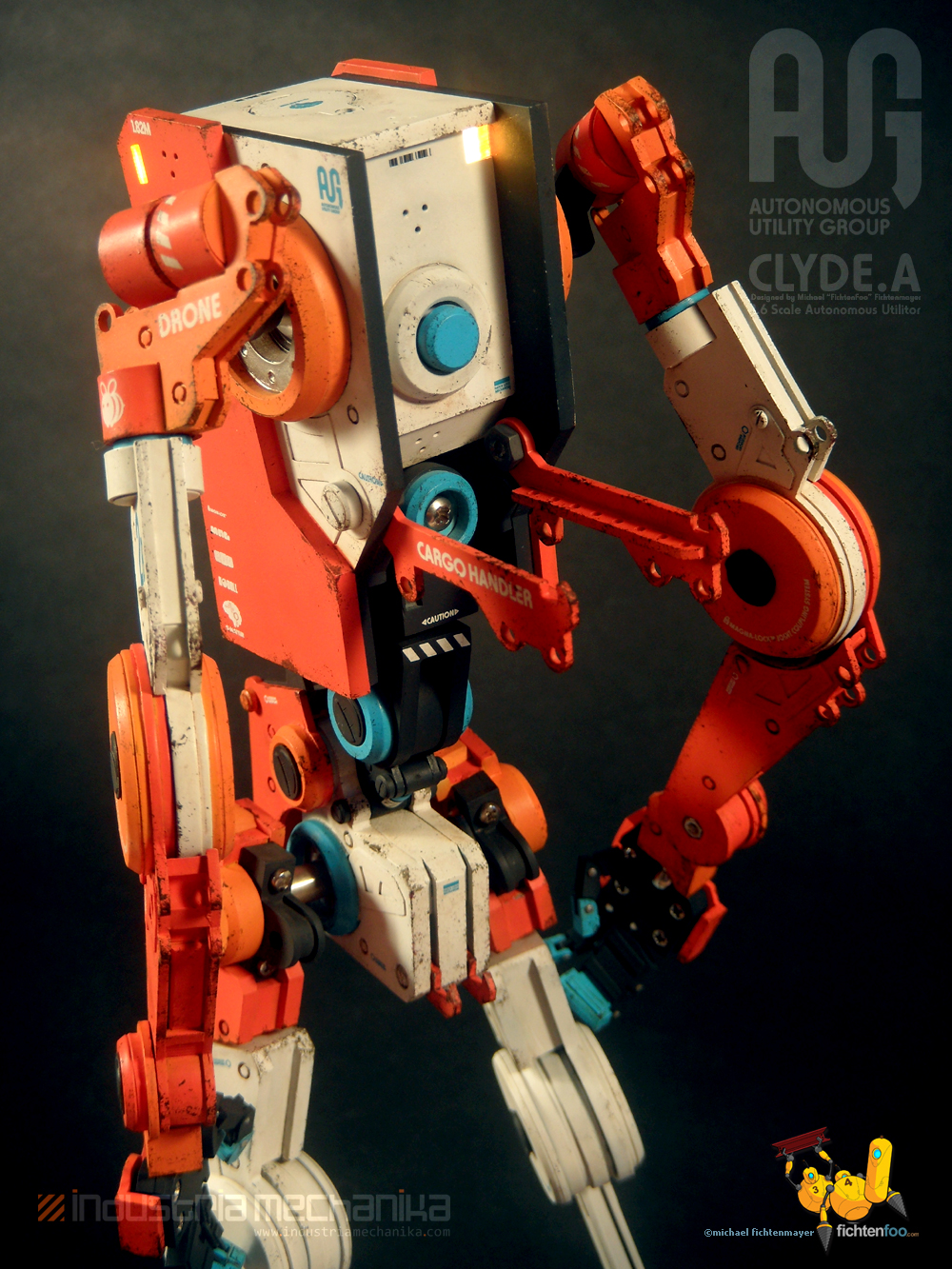

Enter the Clyde.A! Clyde started with a few basic goals and ideas: create a 1/6 robot resin kit with a unique feel that can be made fully articulated (not glued like typical mecha resin statue kits), and not cost an arm and a leg. One of the largest costs with many of my Industria Mechanika products is the 3D printing and design. Because I have (had, now 90% of what I do is 3D kit and toy design) zero 3D experience and do all of my sculpting by hand, or at most with laser-cut parts I’ve designed, 3D and it’s associated costs were easily avoided.

Because my background is in graphic design, (over 25 years now) I decided to create most of the Clyde.A as vector art which I could break-up into parts which could be laser-cut and etched. This is something I’ve been doing for a while anyway with many of my prototypes and the body of the 1/6 INT-4 mini-rig, so it’s something I am comfortable with. There’s little tricks like knowing how wide the laser-cut lines will be (kerf) because that makes your parts slightly smaller. Useful when you need to slot parts together accurately. Also 1/8″ thick acrylic is NOT 1/8″ thick. None of it is correctly marked, but it’s mostly consistent, so I make ample use of my digital calipers. Also I found myself using a lot of the skills I learned during a few months of drafting class in 9th grade before we moved to another school district. It’s important to know how wide, long, deep, etc. everything is and how it fits together and these manual skills helped a lot.

Design-wise, I wanted the Clyde.A to have a unique and functional aesthetic. Too many designs these days rely on CG and look over-detailed and layered. Worse than that, most upon inspection do not look functional in the least. Clyde had to look cool, but also have the same range of movement a human has. If I can do it, Clyde has to be able to do it… except for the whole lack of head/neck of course. So much of the design was figuring out how I could articulate the limbs and torso, then build the design around that. The end result is a mecha that has a very utilitarian, construction equipment feel. This is ideal because the backstory of this robot is a low-cost robot to do manual labor. Kind of like my dad who uncoincidentally is also named Clyde who worked as a towboat deckhand on the rivers for most of his adult life until retirement.

The backstory led me to create a fictional company called “Autonomous Utility Group”, AUG for short, who designs and manufactures consumer robotics. This let me flex my design muscles creating logos for it and a slew of supplier products for the decal sheet. Mag-Lock, RoBall, EGO, G-Matter, MAG, and Tuff-Grip. A lot of my inspiration came from playing WipEout Omega and having been a loooong time fan of the Designers Republic’s work on the franchise.

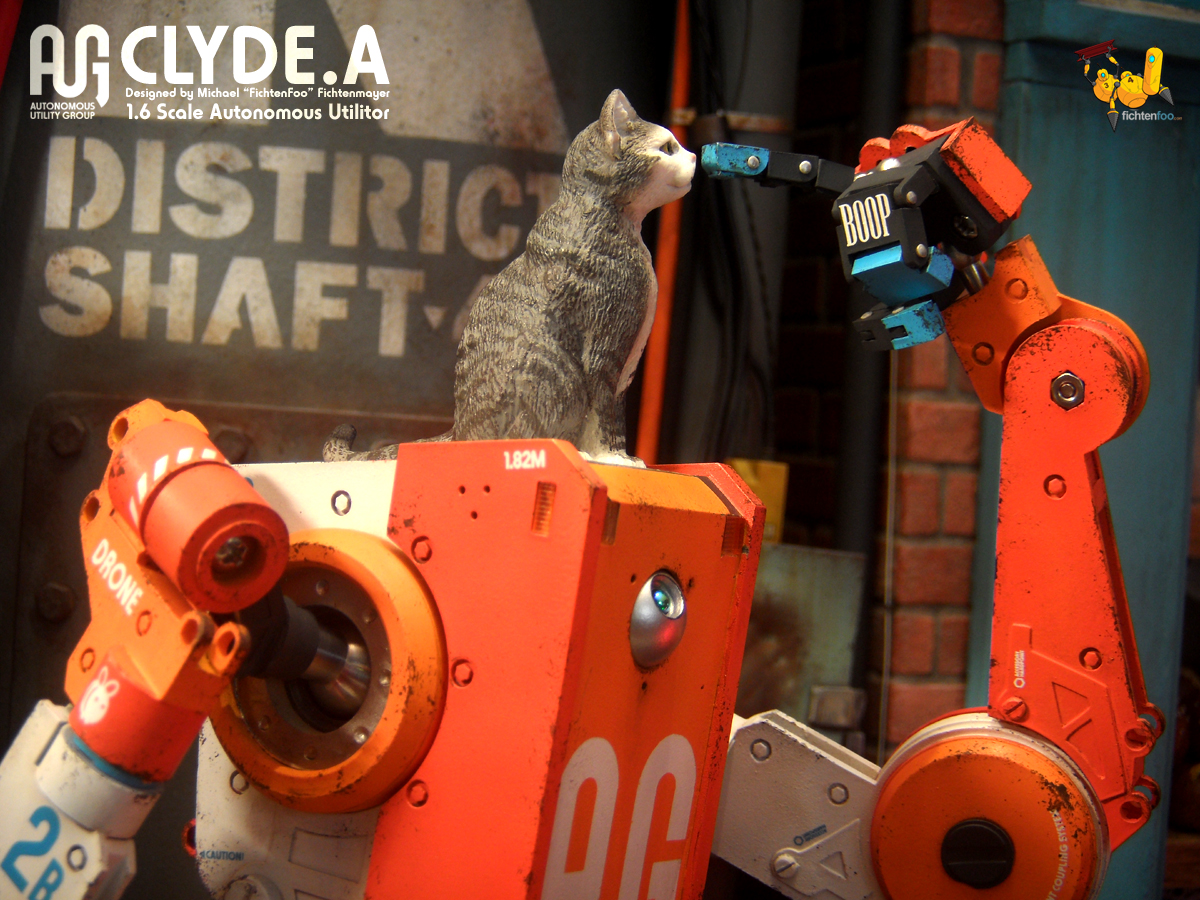

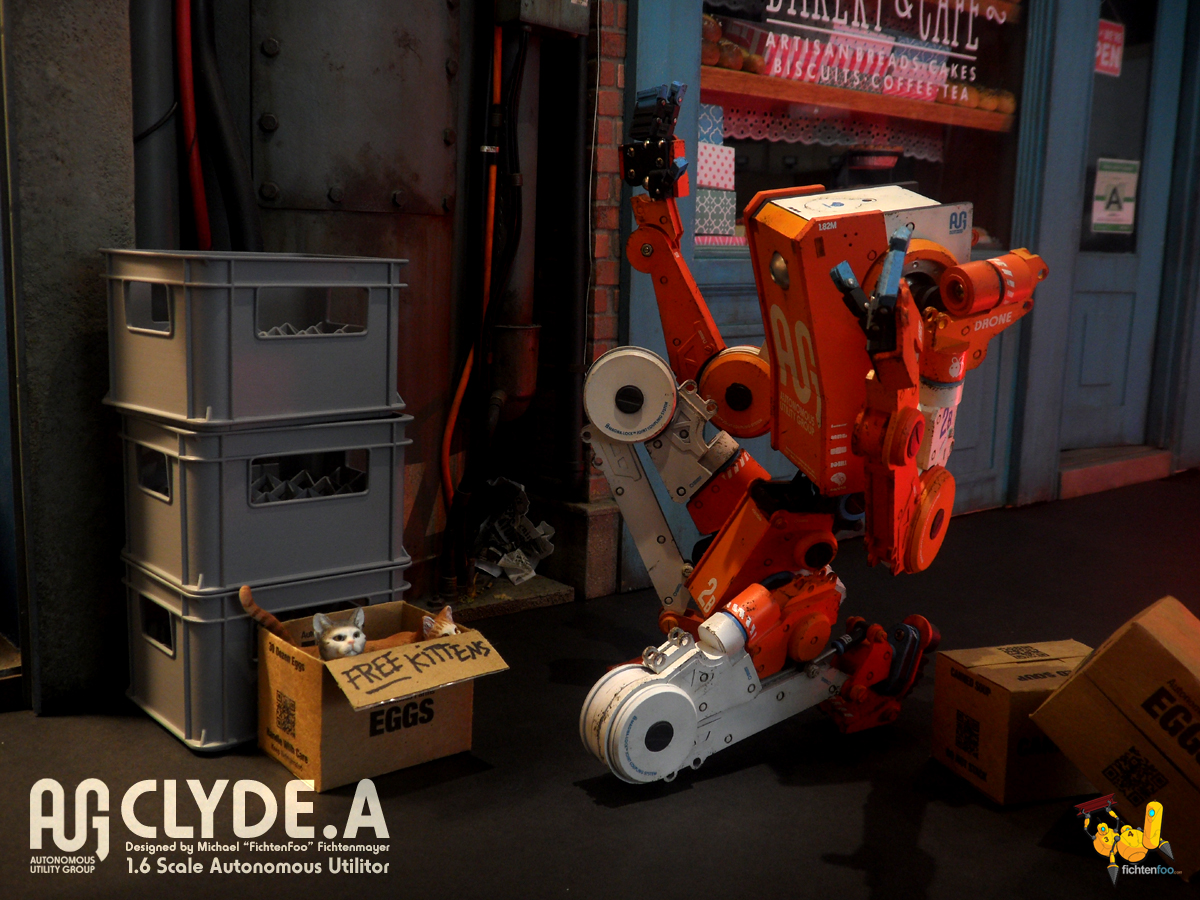

Once I had all of the laser-cut parts designed in November 2017, I sent the prepped files to my vendor cut them from the appropriate acrylic thicknesses. Unfortunately he was in the middle of moving his shop, then some laser malfunctions, etc… just bad luck and bad timing. So where I typically get parts back in a few weeks, I didn’t get the Clyde parts back until April. But instead of sitting on my thumbs, I decided that a cool robot needs a cool cyberpunk backdrop to be photographed in front of. So I spent December-April designing and fabricating 3 modular building pieces. A Ramen shop, Some sort of shaft set-piece, and a Bakery. I also have parts to do a dive bar which I hope to do later this year.

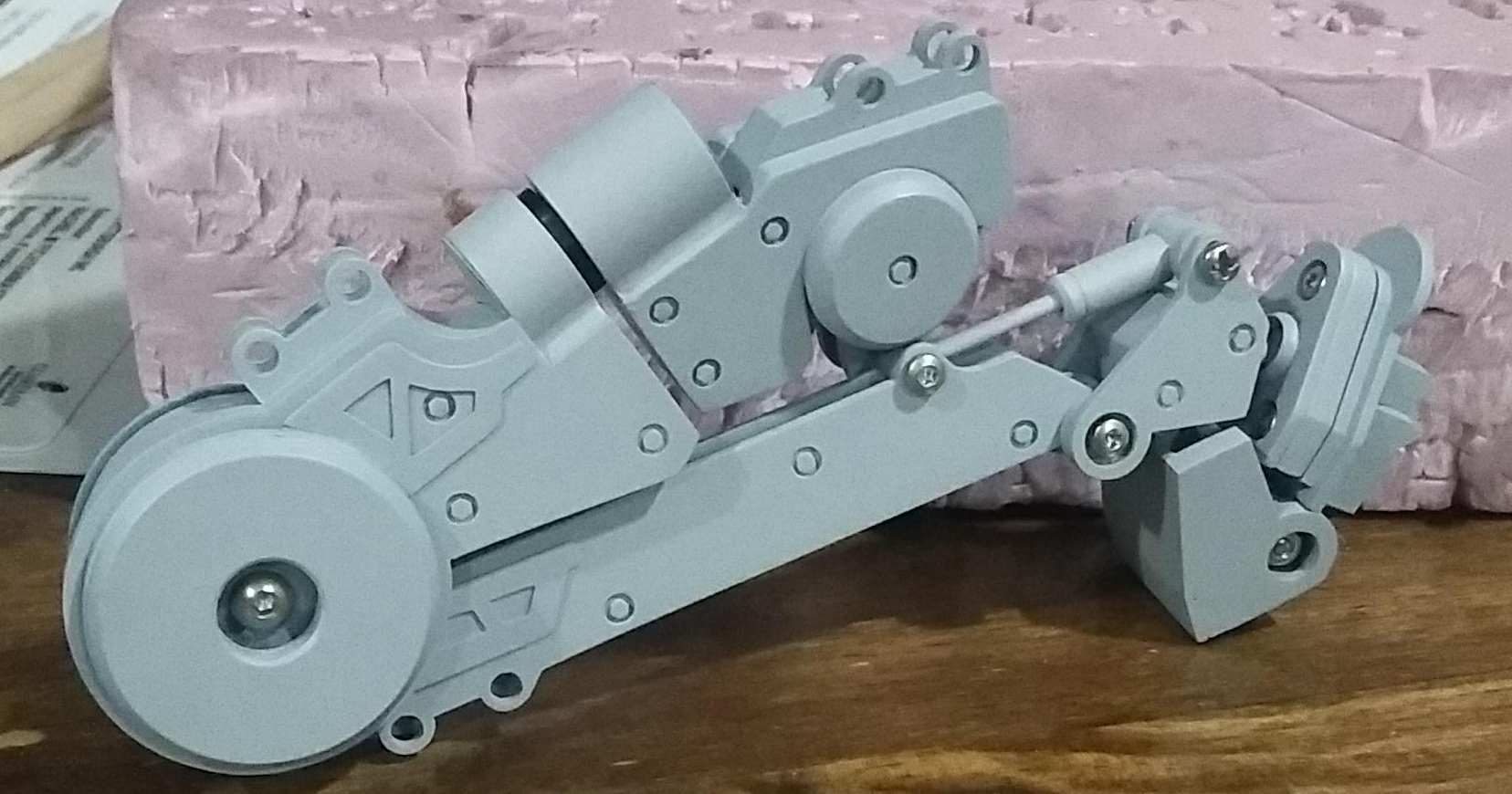

Once the parts arrived, I set to work gluing them together, sanding, shaping, sizing appropriate hardware, etc… This took weeks to do despite all the pre-work I’d done on the design. I wanted to make sure that everything was perfect, clean, and functional. While I made plastic ball-joints for the master initially, I realized quickly that metal would be better in that it wouldn’t need to be painted (no chipped/rubbed off paint!) and would not break, especially the fingers. So I designed the ball-pegs and my laser-cutting vendor sent them to a machinist for me. Despite that, I could not do a full pre-build to take enticing pics to get people to preorder my latest creation. To do so would mean gluing the ball-joints in-place and that would cause damage to the master I’d spent so much time perfecting. Best I could do is show off some sub-assemblies. That at least showed me that I needed to redesign the feet. I managed one full body pic before the toe redesign however the pic made the design look so bad that it was better to keep it a secret and hope that people would trust me to make a good bot. 30-some people did, more than half my first batch of kits, so to have earned that trust means a lot to me.

So I sent the master parts to my caster in June and expected to have the Clyde.A shipping out by Christmas. Best… Laid… Plans… 2018 was a bad year production-wise and I’m still recovering and waiting on other delayed new products such as out die-cast photoetch car details sets. As it turned out, xmas came and went and I didn’t get my resin until a few weeks ago. As soon as it was in my grasp however, I made the instruction sheets, and started building one up.

So enjoy the pics of the first ever 1/6 Clyde.A built by its creator, displayed in front of his cyberpunk backdrop.

![Maude [Cyborg Action-Doll] (Files Only)](https://fichtenfoo.net/blog/wp-content/uploads/2023/01/Maude-Promos-300x300.jpg)